Seven Technologies from the World of Concrete

by Wendy Lau

Seven Technologies from the World of Concrete for the World of Architecture

Smirk all you want at the name World of Concrete, but the tradeshow is about more than brick-laying competitions and jaw-dropping displays of heavy equipment. It’s also about demonstrating progress in the construction trades. The annual show took over the Las Vegas Convention Center from Jan. 20 to Jan. 24. And when we say took over, we mean that 48,000 attendees and 1,250 exhibitors filled the convention center’s North, South, and Central halls, and its Silver and Gold parking lots. Attendees did sway toward the contracting and trades side, but for being in an industry that’s often accused of dragging its feet in the changing times, manufacturers had many advanced—and green!—innovations to show off. We found seven state-of-the-art products for the architectural community.

1. A Remedy for Freeze-Thaw and Unsightly Expansion Joints

Without diving too deep into the chemistry of concrete, here’s a mixture that claims to mitigate the effects of hydration, or the exothermic water–cement reaction that forms the strong molecular bonds in concrete. Cool-Crete eliminates the first-phase of hydration in the curing process, says Cool-Crete Technology Group president Dwayne Dillingham, resulting in concrete that has: a slower set-up time, extending its workability; less porosity and thus less susceptibility to freeze-thaw; less shrinkage, eliminating the need for expansion cuts; and an evenly distributed cure that requires no cooling equipment or humidity control. Applications of concrete with Cool-Crete have successfully been in service for two years in a range of climate conditions, Dillingham says.

Credit: Courtesy CTS Cement Manufacturing Corp.

2. Cooler Clinker Can Reduce Concrete’s Embodied Energy

Though calcium sulfoaluminate (CSA) cement has been around since the 1970s, it hasn’t made many front pages. But, as CTS Cement Manufacturing Corp. discussed at WOC, CSA cement offers performance and environmental benefits, beginning with the clinker. CSA clinker—comprising a mix of limestone, bauxite, and gypsum—requires less limestone, the primary source behind cement’s carbon dioxide emissions. The clinker is also fired at a lower temperature than portland cement—2250 F vs. 2700 F—and is easier to grind, further reducing the energy needed during its production. Concrete made with CSA cement can achieve 28-day strength, in excess of 5,000 psi, in 24 hours and has less shrinkage than concrete made with portland cement. The catch: CSA cement is three times more expensive. But when the targeted service life tops 50 years, the added upfront investment may be worth it.

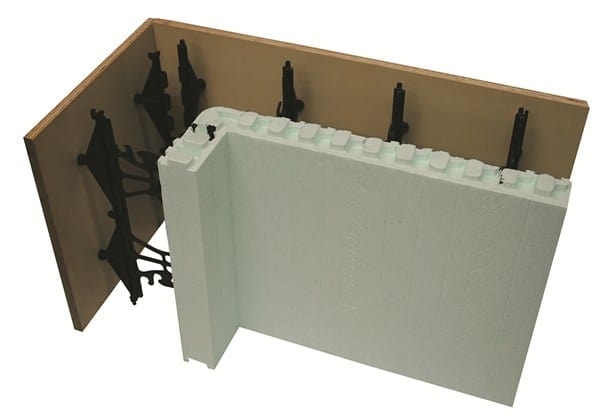

3. Get Energy Efficiency with a Side of Exposed Concrete

Insulated concrete forms (ICF) may not be the sexiest building component, but they do make for rapidly constructible, high-performance envelopes with insulation values upwards of R-50. ICF manufacturer Nudura puts a twist on the conventional forming methods with its One Series. Instead of the typical insulation–concrete–insulation sandwich, the modular form system is an open-faced sandwich of insulation board, concrete, and a removable and reusable composite ply form. In areas where an exposed concrete wall is desired, such as a minimalist interior or a stair tower, workers don’t have to scrap off the unneeded insulation board, saving time, money, and material.

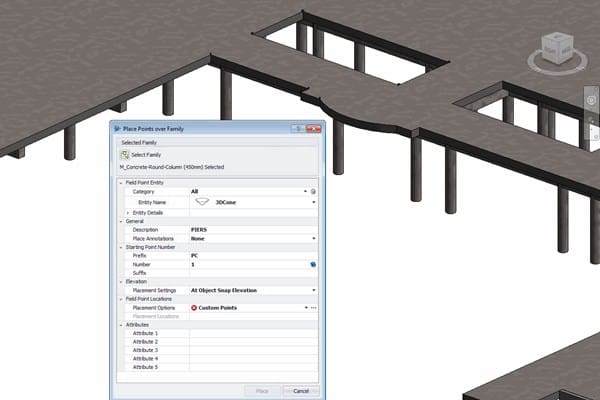

4. Track Field Points and Building Materials Like Your Online Purchases

Though BIM is still making its way through architectural firms, many contractors have jumped on the bandwagon. Now here’s another way for designers and contractors to see eye-to-eye. Trimble Field Points lets designers set field points in CAD and Autodesk Revit files at critical locations, such as anchor points and sleeve locations. Points created in the software plugin can then be exported to Trimble Field Link programs and checked in the field.

Autodesk Revit users can place field points at a specific location on one object family and then let Trimble Field Points populate all matching object family items in the building model with the field points.

Credit: Trimble

Accompanying the software launch is Trimble’s ongoing development of a digital material tracking feature in Meridian Systems’ Prolog project management software (Trimble acquired Meridian in 2006). Successful buildings comprise thousands of materials assembled together in a meticulous, prescribed fashion. Project teams should know the location of all the rebar, bricks, piping, and so on that will compose our buildings from the moment it leaves its maker to when it’s installed on site. Trimble is currently working with suppliers and contractors on the system’s logistics, but it expects to introduce material tracking later this year.

5. Add Sparkle, Pat Self on Back

In 2001, American Specialty Glass got its start by salvaging discarded bottles and windows into glass chips for terrazzo flooring. The Salt Lake City–based company now operates multiple glass-melting furnaces and offers glass aggregate in custom formulations for landscaping, countertops, swimming pools, and more. One thing that has stayed constant: the use of 100% recycled glass. Many eye-catching colors and sizes are in stock, including the sunshine mix glass nuggets in small (shown).

6. Floors Can Look Good and Fight Sound, Fire, and Unevenness

If floors don’t seem as level as they should be, don’t cover up the problem with carpet. USG Corp.’s UltraArmor is a fast-setting, cementitious underlayment that can be applied directly to concrete, wood, radiant heat, or steel deck surfaces with minimal prep work. Walk right on it after three hours, assuming normal curing conditions. After the fire-resistant, sound-attenuating, gypsum-based product levels the flooring substrate, UltraArmor can be left exposed, sealed and stained in many colors, adding floor finish to its list of achievements.

Credit: Wanda Lau

7. It’s More than a Sallow Sack

Beyond its characteristic yellow sacks of concrete and mortar mixes, Quikrete is expanding its palette with a line of concrete and masonry stains. The company’s Concrete Etching Stains are made with organic acids and react with cement, creating a permanent, marbleized effect on an existing exterior or interior flooring surface. Quikrete’s water-based Translucent and Penetrating Concrete Stains are low VOC, low odor, and nontoxic. Available in several colors, the stains can add dimensionality to concrete’s understated appearance.

Credit: Quikrete

0 comments