Better Garage Floors

Tips for pouring stronger, crack-free concrete slabs for better garage floors

by William D. Palmer Jr. and Paul Newman

Garage slabs take a lot of abuse. They have to support heavy cars and trucks and resist ice, dirt, salty water, de-icers, gasoline, motor oil, antifreeze, and other contaminants. Plus, since few garages are heated, they have to tolerate freeze/thaw conditions. But a garage slab that has been carefully planned, installed, and cured should have no trouble providing years of crack-free performance in any climate, even under the toughest conditions. Commercial concrete contractors do this kind of work every day; with attention to detail and high standard of quality.

For better garage floors, start with a Good Base

Don’t worry too much about your soil’s bearing capacity. Even poor soils like silt and soft clay have an allowable soil pressure of around 400 pounds per square foot (psf). A 6-inch-thick slab weighs only about 75 psf, and live loads — anything that is not part of the building itself, including vehicles—typically don’t exceed 50 psf in a garage. That means that the soil under a typical garage slab only has to be able to support 125 psf.

Far more important than bearing capacity is the base’s ability to provide consistent support. If one part settles more than another, the slab will bend and potentially crack. To avoid this problem, you need to know which areas have been cut and filled, and then you need to make sure that filled areas have been well-compacted. Any soil that’s been disturbed during excavation must also be compacted. Keep in mind that it’s hard to get good compaction with soil that is too dry or too wet. To test for moisture content, squeeze a handful of soil. If you can squeeze out water, it’s too wet, and if it falls apart when you open your hand, it’s too dry. If it holds its shape, it’s about right.

The safest approach is to remove the topsoil and place a minimum 4-inch layer of compactible gravel or crushed stone as a base over the undisturbed subsoil. Use unwashed material that has a top size of 11/4 inches and includes smaller sizes right down to the fines; the irregular shapes and sizes interlock nicely when compacted. Gravel or stone provides a layer for the installation of underslab conduit and pipes, allows for water and radon to escape, and helps keep the slab thickness uniform, which saves money on concrete. It also helps spread the load over the underlying soil, so that the slab is supported more evenly. Plus, it’s easy to compact and hand-grade.

Probably the most difficult soil you will have to deal with is expansive clay, which swells when it’s wet and shrinks when it dries, and can’t be compacted easily. It’s best to remove this clay and replace it with a compactible fill. If that’s impractical, you should consult with a foundation engineer. In some cases, the engineer may recommend structural slabs or post-tensioned slabs that don’t rely on the soil for structural support.

Install a vapor barrier for better garage floors

Most building codes say that an unheated detached garage doesn’t require a vapor barrier, but that doesn’t mean you shouldn’t install one anyway. Moisture in the ground can wick up via capillary action, and water vapor is always present beneath slabs; any air in the subbase is almost always at 100 percent relative humidity. Without a vapor barrier, moisture will move through the concrete and condense beneath anything stored on the slab surface, leaving telltale dark spots. In extreme cases, the slab will even “sweat.” If the slab is ever covered with flooring or a finish coating, the moisture could cause delamination. A vapor barrier is cheap insurance.

Most building codes say that an unheated detached garage doesn’t require a vapor barrier, but that doesn’t mean you shouldn’t install one anyway. Moisture in the ground can wick up via capillary action, and water vapor is always present beneath slabs; any air in the subbase is almost always at 100 percent relative humidity. Without a vapor barrier, moisture will move through the concrete and condense beneath anything stored on the slab surface, leaving telltale dark spots. In extreme cases, the slab will even “sweat.” If the slab is ever covered with flooring or a finish coating, the moisture could cause delamination. A vapor barrier is cheap insurance.

Although 6-mil poly will satisfy IRC requirements, 10-mil or thicker vapor barriers designed specifically for use under slabs are less likely to puncture or deteriorate. Some examples are VaporBlock (www.vaporblock.com), Stego Wrap (www.stegoindustries.com), Griffolyn (www.reefindustries.com), and Perminator (www.wrmeadows.com).

The vapor barrier should be placed on top of the subbase, directly underneath the concrete. If you’re installing rigid foam under the slab, put the vapor barrier on top of the foam.

Don’t place a sand or gravel blotter layer on top of the vapor barrier. There was a time when that practice was recommended to reduce curling in the slab, but if you’re using the proper low-water-content concrete mix, a blotter layer is unnecessary. It can actually trap moisture, which will then keep rising up through the slab.

The vapor barrier’s seams should overlap at least 6 inches and be sealed with tape. To prevent concrete from pushing into them and tearing the material during placement, try to orient the seams so that they will be parallel to the direction of concrete placement.

Don’t add water to the mix

The IRC requires that slabs be built with concrete with compressive strengths from 2500 to 3500 psi, depending on the climate. ACI goes further and recommends 4500-psi concrete for garages in the northern half of the country. To achieve this strength, the water-cement ratio should be kept at 0.5 or less, typically about a 5-inch slump concrete. Because this mix is slightly dry and stiff, it’s tempting to add water to make the concrete easier to place. But be careful: There’s an inverse relationship between the eventual compressive strength of concrete and the amount of water used in the mix—the higher the water-cement ratio, the lower the strength. The best way to get concrete that flows well enough to consolidate in the forms and around the reinforcement is to use a high-range water reducer, or super-plasticizer.

Super-plasticizers work by pushing the cement grains apart, so that the mix flows more easily.

For better garage floors, use air-entrained concrete

Most garage floors are not made with air-entrained concrete because finishers don’t like its sticky consistency. However, this type of concrete is essential in any climate that experiences freezing temperatures. Entrained air is accomplished by adding a soaplike admixture that froths to produce billions of microscopic air bubbles. These bubbles relieve internal pressure in the concrete by providing tiny chambers for water to expand into when it freezes. Without air-entrainment, concrete exposed to freeze-thaw cycles will scale, or flake off, at the surface, and may eventually disintegrate.

The amount of entrained air required depends on the maximum aggregate size; less air is needed with larger aggregate. Climate is also a consideration, though there are only a few regions across the southern U.S. that fall outside ACI’s moderate and severe weathering zones (see map, page 26). With 3/4-inch top-size aggregate, for example, ACI recommends 5 percent air entrainment in moderate regions and 7 percent in severe regions.

How do you know you’re getting concrete with the proper water-cement ratio and strength and air content? Unless you learn to do some tests or hire a testing company, you’re going to have to trust your ready-mix provider. You can check the batch ticket, but your best insurance is a good relationship with the concrete producer. Be clear about what you want and what the concrete will be used for, and the company will adjust the mix accordingly.

Isolate the slab

All slabs settle to some extent, while foundation walls and columns are usually more stable. Slabs also shrink as they dry, and they continue to expand and contract with changes in temperature. Using isolation joints around the perimeter of the slab and around any penetrations allows it to move independently and helps prevent cracks.

Isolation joints should be made from 1/2-inch-thick materials like asphalt-impregnated fiberboard, neoprene, and even cork. Some builders use sill seal to make isolation joints, but this material is only 1/4 inch thick. Though it may serve as a bond break, it might not create a big enough gap to allow for differential movement between the slab and the foundation walls. Regardless of the material you use, the joint must be set at the proper grade and be at least as wide as the thickness of the slab, so the slab won’t partially bond to the walls.

Is wire mesh really necessary?

Most garage slabs have embedded steel reinforcement. This steel rarely serves a structural purpose; instead, it’s intended to keep small cracks in the slab from opening wider. However, with a good uniform subbase, a low-shrinkage concrete mix, and proper joint spacing, a slab is unlikely to have a lot of problems with random cracking, even without rebar or welded wire fabric or mesh reinforcement. For that reason, a growing number of contractors are pouring their garage slabs without steel.

If you do use steel use flat sheets rather than rolls of mesh, which are difficult to handle and nearly impossible to flatten. For most garage slabs, a grid of #3 rebar at 18 inches on-center in each direction provides better reinforcement than mesh and is easier to install. Use rebar with wire mesh to beef up parts of the slab that are particularly vulnerable to cracking. For instance, we recommend placing a couple of 4-foot-long #3 bars diagonally across re-entrant corners.

Reinforcing steel won’t do much good if it isn’t centered vertically in the slab. This can be done by suspending mesh or rebar on pieces of concrete brick or on small supports (chairs) during the pour. Hooking and pulling unchaired mesh isn’t effective because the mesh gets walked on again and goes back to the bottom of the concrete. Some contractors even install a double layer of mesh; the lower layer props up the second layer and keeps it higher in the slab.

Use fiber reinforcement for better garage floors

At about $8 per cubic yard, fiber reinforcement is a relatively inexpensive way to improve the surface of the slab and add extra impact and abrasion resistance. The fibers won’t do much to prevent shrinkage cracking (the typical random cracks that develop in the slab as it dries), but they can be very effective at reducing plastic-shrinkage cracks, or crazing (the network of finely spaced, very thin cracks in the concrete surface). Made of polypropylene or nylon, these fibers are mixed in with the concrete before placement and improve mix cohesion.

Be aware that fiber reinforcement can affect the way the concrete is placed and finished; slump is reduced a bit and it is sometimes necessary to use a vibrating screed to bury the fibers. If strike off is done by hand, the finished surface can sometimes look a little hairy, but that quickly wears off with traffic.

[column size=”two-third”]

Finishing Timeline

Place concrete within 90 minutes after it leaves the ready-mix plant.

-

- [list type=”check”]

- Screed immediately after spreading and consolidating concrete.

- Bull-float or darby as soon as possible after screeding and before bleedwater appears.

- Allow all bleedwater to rise to the surface and evaporate; concrete should be hardened enough so that footprints are 1/4 inch deep or less.

- Edge the concrete and cut tooled joints, if desired (not necessary if saw-cutting joints).

- Float the concrete to embed aggregate, remove imperfections, and consolidate surface.

- Trowel to produce a hard, flat surface.

- Saw joints with early-entry saw in one to four hours.

- Saw joints with traditional wet-cut saw after four to 12 hours (as soon as concrete can be sawed without aggregate loosening).

[/list][/column]

[column size=”one-third” last=”true”]

Don’t start finishing too soon

Even though air-entrained concrete won’t bleed much, you shouldn’t trowel the surface until whatever bleedwater there is has evaporated and the concrete has gained enough strength to support finishing operations. If bleedwater is still present, troweling will work it into the surface of the concrete, creating a soft top layer prone to dusting, scaling, and crazing. Use the thumbprint method; a 1/4-inch thumbprint impression means the concrete is set up enough to begin final finishing.

(See “Finishing Timeline” on the left.) [/column]

Saw-cut contraction joints

As concrete dries, it shrinks and cracks. Contraction joints, or control joints, create planes of weakness in the slab that help it crack where you want it to crack and in straight lines.

In order to get shrinkage to activate the contraction joint properly, the depth of the joint should be equal to one-quarter the thickness of the slab. Contraction joint spacing should be two to three times in feet what the slab thickness is in inches. That means that a 5-inch-thick slab should have 11/4-inch-deep control joints spaced 10 to 15 feet apart (slightly closer for wetter concrete). Panels formed by these control joints should be as close to square as conditions allow.

Some contractors use plastic zip strips to make contraction joints, but it’s difficult to pull off the “zip” section of the strip without creating a rough-looking joint. Hand-tooled joints often are not deep enough to be effective, so we recommend saw-cut control joints. They’re deeper and more consistent, which reduces the likelihood of random cracking. Early-entry dry-cut saws are better than conventional water-cooled saws because they can be used within one to two hours after finishing, before shrinkage cracks have a chance to form.

Cure the surface properly

A slab will shrink and crack like a parched mud puddle if the surface is allowed to dry too quickly. Cement can’t hydrate without water, so a dry surface will create a weak layer in the very place where you want the concrete to be strongest. Poorly cured surfaces end up with crazing cracks and dusting, and the entire slab may curl upward at the edges if the top dries more rapidly than the bottom.

One way to make sure this doesn’t happen is to spray a membrane-forming curing compound (or a cure-and-seal)onto the surface. This will create a thin impermeable membrane that traps the slab’s own moisture and prevents premature drying. Some compounds can be colored with white pigment so it’s easier to see where they’ve been sprayed.

Curing compounds can interfere with adhesion, though, so if the slab will be getting some sort of coating, a better option might be to use poly sheeting or curing blankets. Poly is inexpensive but can leave mottled marks on the floor.

Curing blankets like HydraCure S16 (www.pna-inc.com) produce reliable curing and a more even appearance. The S16 is a single-use product, but multiuse blankets that can be rinsed and stored are also available from HydraCure and other manufacturers. Curing blankets for cold-weather are usually insulated and sometimes even heated; they’re often available for rent. Fasten the poly or blankets at the edges so they don’t blow away.

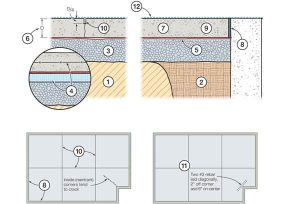

Crack-Free Slab Details

1. Undisturbed subsoil. Remove problem soils like expansive clay or organics and replace with compacted fill.

2. Sand and gravel back fill compacted in 4- to 6-inch lifts.

3. Minimum 4-inch-thick compacted sub base of unwashed crushed stone or gravel.

4. For radiant slab, install 1- to 2-inch rigid EPS insulation followed by vapor barrier. Reinforce slab with 6×6 W2.9xW2.9 welded wire reinforcement centered vertically in the slab and discontinued at the joints. Support the wire during concrete placement; do not hook into position.

5. 10-mil (min.) plastic vapor barrier, seams overlapped 6 inches and sealed with tape.

6. Minimum 4-inch slab (5 inches for heavy trucks), 3500-psi (min.) concrete, 4500-psi concrete for severe weathering areas.

7. Use low-water-content air-entrained concrete (5% to 7% air entrainment) in freezing climates and 11/4-inch (top size) aggregate.

8. 1/2-inch isolation joints around perimeter and at penetrations through slab (such as columns).

9. Fiber reinforcement added to mix at plant, typically 1.5 pounds per cubic yard, to reduce plastic shrinkage cracking.

10. Saw-cut contraction joints, depth equal to one-fourth the slab thickness and spaced two to three times in feet the thickness of the slab in inches (so a 4-inch slab should be cut 1-inch-deep every 8 to 12 feet. Keep panels as square as possible.

11. Reinforce inside (reentrant) corners with 4-foot lengths of #3 rebar laid diagonally to minimize cracking.

12. Spray-on curing compound or curing blankets (leave curing blankets in place for seven days after concrete placement).

0 comments